Introduction

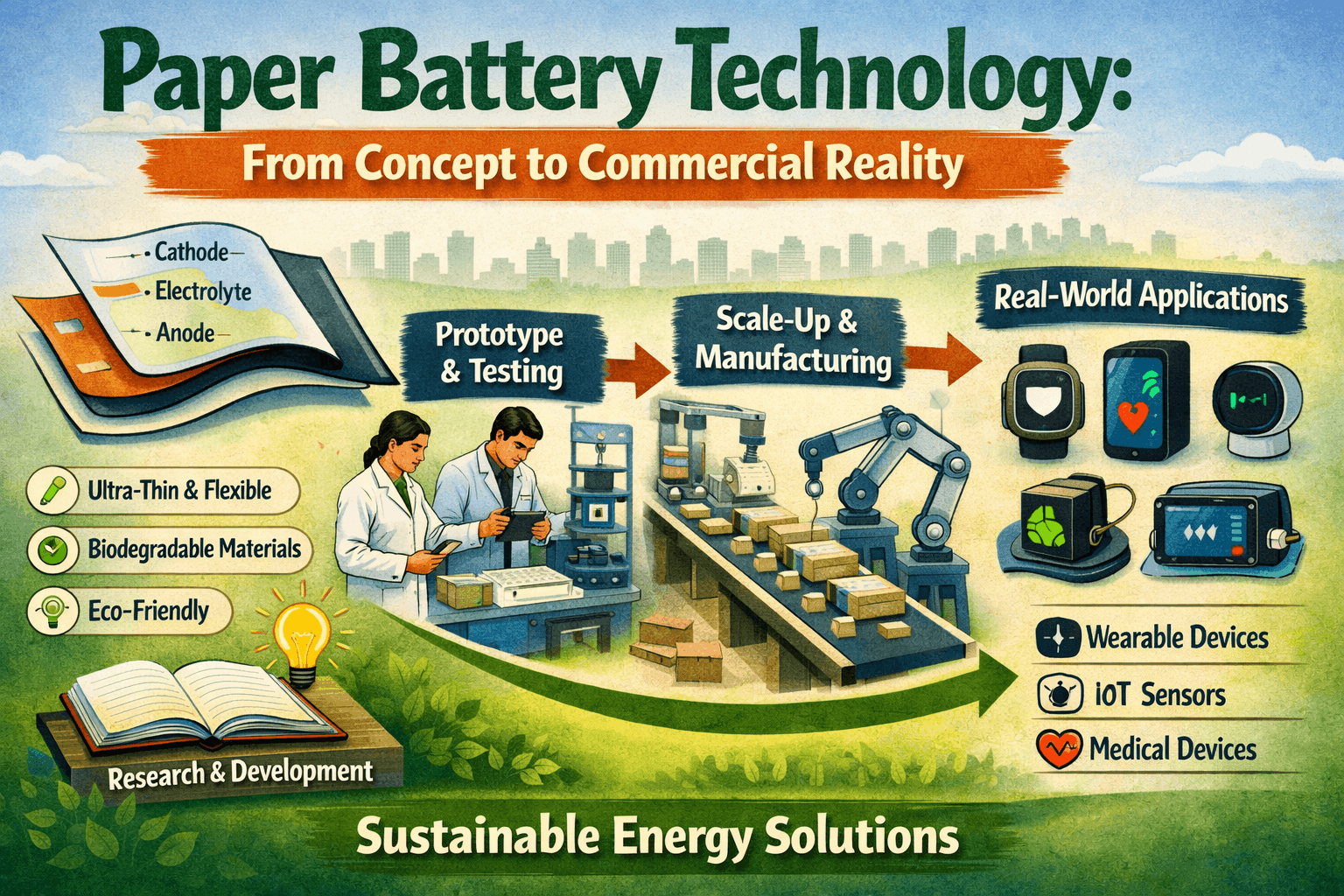

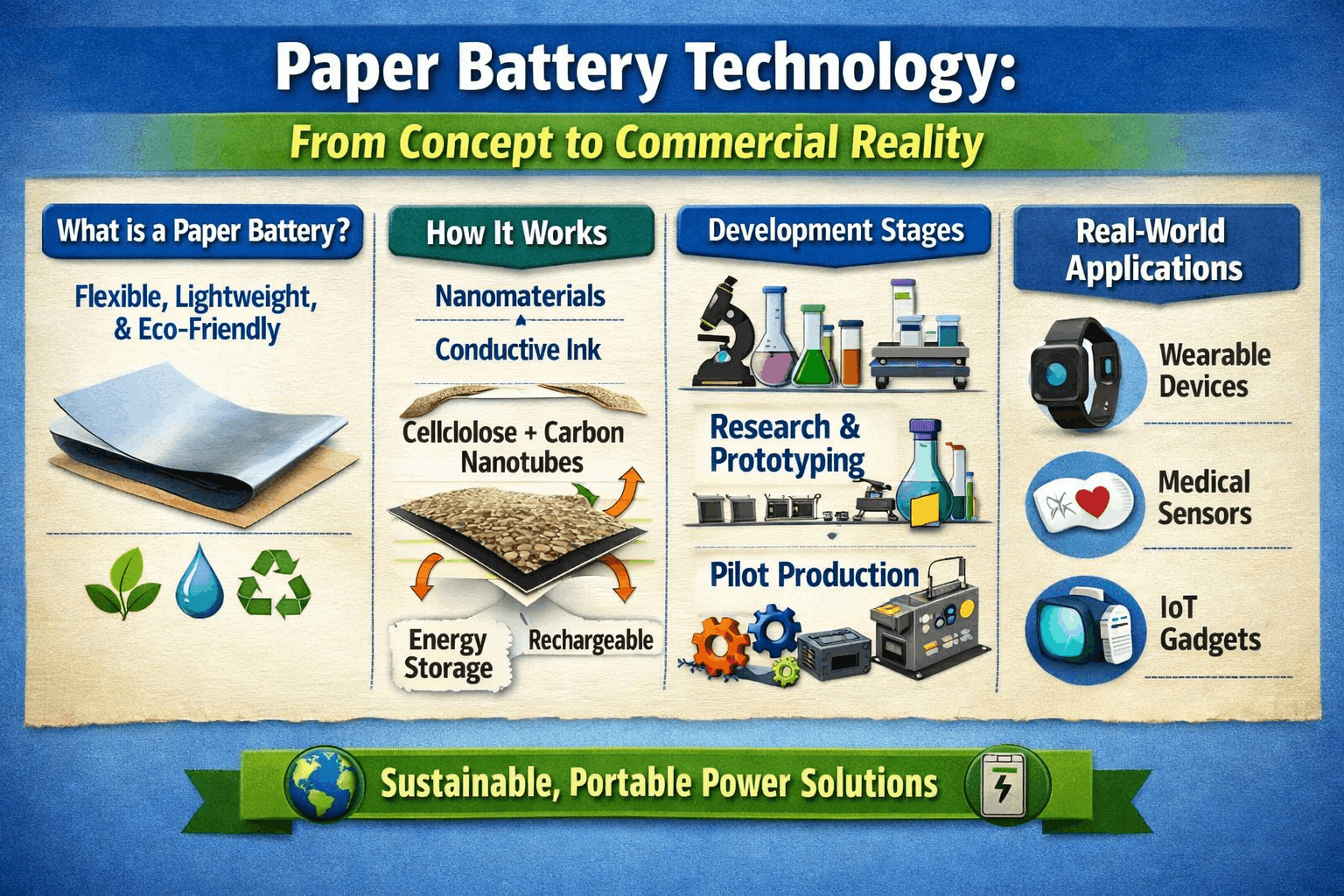

A Paper Battery is an advanced energy storage device engineered using a spacer primarily composed of cellulose, the fundamental constituent of paper, integrated with nanoscale materials that serve as electrodes. This innovative Paper Battery technology represents a significant departure from conventional metal-based energy storage by leveraging renewable, biodegradable materials to create flexible battery solutions. While the fundamental principles of electricity generation mirror those of traditional batteries, the architecture is uniquely sustainable, offering a path toward truly biodegradable electronics and energy systems.

The evolution of Paper Battery technology has accelerated from a laboratory concept to a commercial product. Companies like Singapore-based Flint have now entered the production phase, marking a pivotal moment where these sustainable cells are available for pilot deployments in real consumer devices.

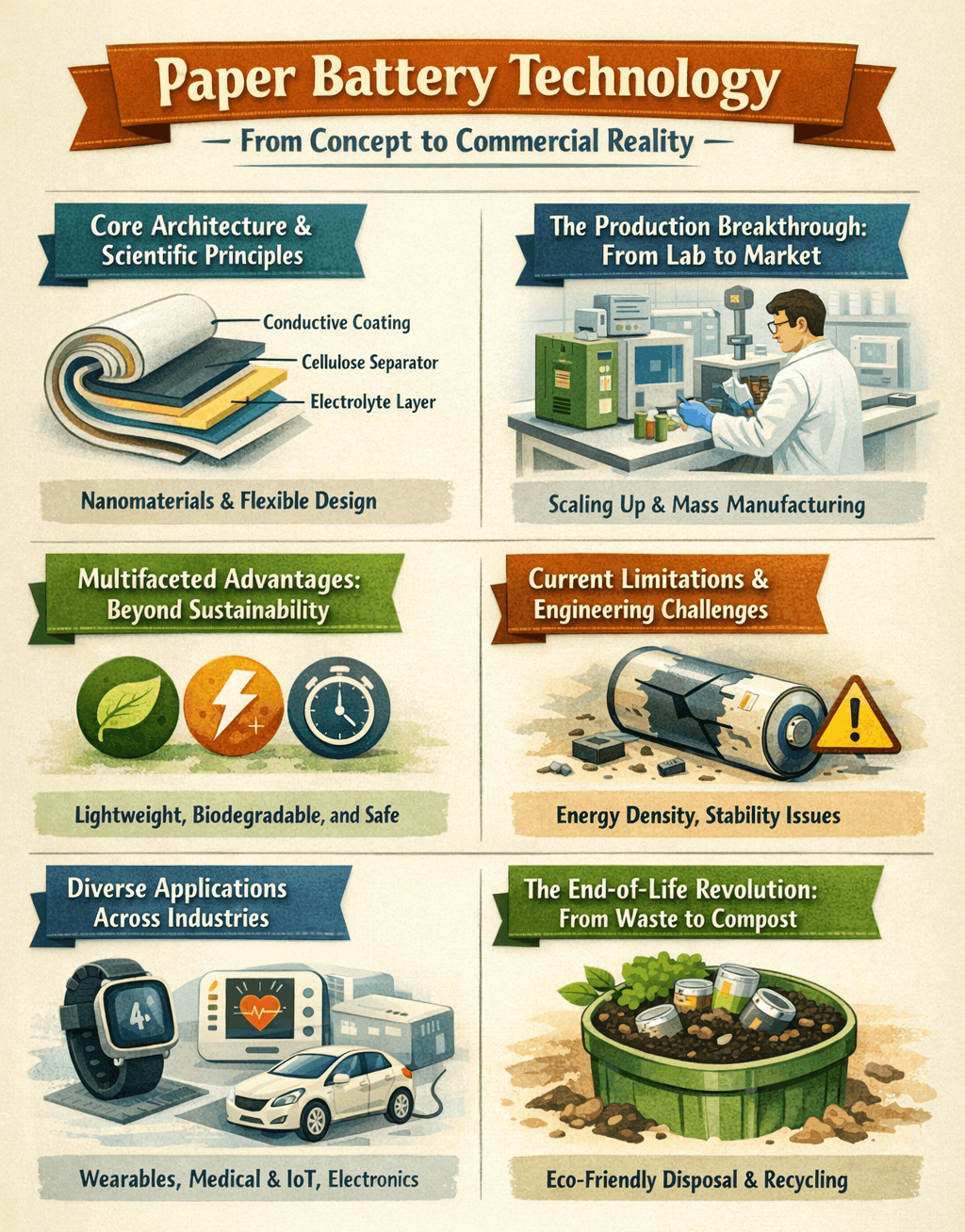

Core Architecture and Scientific Principles

A paper battery’s function is deceptively simple, hinging on the unique properties of cellulose. The cellulose matrix acts as both a structural scaffold and a natural medium for ion transfer, replacing the plastic separators and complex housings found in conventional batteries.

- Primary Components: The standard configuration includes an anode (such as zinc), a cathode (such as manganese), a water-based electrolyte (like a hydrogel), and the cellulose separator. This composition eliminates the need for critical minerals like lithium, cobalt, and nickel.

- Ion Transfer Mechanism: The porous, fibrous nature of cellulose provides a vast internal surface area. This structure facilitates highly efficient capillary action, allowing the electrolyte and ions to move freely without external pumps, enhancing conductivity and power output.

The Production Breakthrough: From Lab to Market

The long-held vision for paper batteries has materialized with the start of commercial production. Flint’s 8,000+ square foot facility in Singapore operates a purpose-built, water-based manufacturing line, proving that a non-lithium, lower-carbon battery supply chain is viable outside traditional centers.

This shift from prototype to product is validated by partnerships with major technology firms, including Logitech and Amazon Devices, for integration into consumer electronics. This commercial traction answers a critical question: Can a sustainable battery meet the performance and scalability demands of the global electronics industry?

Multifaceted Advantages: Beyond Sustainability

The benefits of paper batteries extend well beyond their environmental profile, offering tangible performance and safety upgrades.

- Superior Safety Profile: Utilizing non-flammable, water-based electrolytes makes these batteries inherently safer. Demonstrations show they can continue operating when bent, punctured, or exposed to direct flame without leaking, exploding, or emitting toxic fumes.

- Mechanical and Design Flexibility: The thin, paper-like structure allows the battery to be bent, folded, or cut to fit novel form factors. This enables seamless integration into wearable technology, flexible displays, and medical patches where rigid batteries are a limitation.

- Economic and Supply Chain Resilience: Early analyses suggest production costs can be significantly lower—reportedly 8 times cheaper per kWh than lithium-ion batteries—due to abundant, non-toxic materials. Manufacturing can be decentralized, using regionally sourced cellulose, even from invasive plant species, reducing geopolitical supply chain risks.

Current Limitations and Engineering Challenges

Despite the promise, several technical and economic hurdles must be navigated for widespread adoption.

- Energy Density and Power: Current iterations often have lower energy density compared to advanced lithium-ion batteries, making them better suited for low-power electronics rather than electric vehicles in the immediate term.

- Material Durability: Pure cellulose has low shear strength, making early prototypes prone to tearing. Enhancements through nanocomposites or specialized coatings are required for rugged applications.

- Manufacturing Complexity and Cost: While material costs are low, processes like integrating carbon nanotubes or precise nanomaterial patterning can be expensive and complex, though next-generation designs aim to simplify this.

Paper Battery vs. Conventional Lithium-Ion Battery

| Feature | Paper Battery | Conventional Lithium-ion |

| Core Materials | Cellulose, Zinc, Manganese, Water-based electrolyte | Lithium, Cobalt, Graphite, Flammable liquid electrolyte |

| Flexibility | Highly flexible and thin | Rigid, requires fixed casing |

| Safety | Non-flammable, non-explosive, leak-proof | Risk of thermal runaway, fire, and leakage |

| End-of-Life | Biodegradable; decomposes in weeks in soil | Requires complex, energy-intensive recycling |

| Current Best Application | Wearables, sensors, disposable medical devices | EVs, high-power electronics, grid storage |

Diverse Applications across Industries

The unique properties of paper batteries open new frontiers in product design and application.

- Disposable Electronics and Medical Diagnostics: Single-use devices like pregnancy tests, environmental sensors, and point-of-care diagnostic patches can be powered by batteries activated by bodily fluids like sweat or blood, then safely composted.

- Wearable and Flexible Electronics: The technology is ideal for powering smart clothing, flexible displays, and lightweight augmented reality glasses where conformability is essential.

- Distributed IoT and Remote Sensors: Low-cost, safe, and sustainable power sources are critical for the billions of sensors in smart agriculture, environmental monitoring, and building management systems.

- Future Potential in Large-Scale Storage: Research into solid-state derivatives and hybrid capacitor designs points toward future applications in home energy storage and as a component in larger grid systems, especially where safety is paramount.

The End-of-Life Revolution: From Waste to Compost

The most radical advantage lies in the battery’s afterlife. After removing the minimal metal components for recycling, the core cellulose-based structure can be buried in soil, where it biodegrades completely within approximately six weeks, leaving no toxic residue. This presents a fundamental shift from a linear “take-make-dispose” model to a circular, biological cycle, directly addressing the growing global crisis of electronic waste.

Conclusion

Paper battery technology has decisively moved from the realm of academic curiosity to a tangible, production-ready innovation. It redefines energy storage not merely through a change in chemistry but through a holistic reimagining of material sourcing, manufacturing, safety, and end-of-life design. While it will not replace lithium-ion batteries in all applications overnight, it establishes a powerful new pillar for a diverse and sustainable energy storage ecosystem. Its true impact will be in powering the future’s ubiquitous, seamless, and environmentally benign electronics.

FAQs

Are paper batteries rechargeable?

Yes, modern commercial paper batteries like those from Flint are designed to be rechargeable, with a lifespan intended to be comparable to traditional batteries for their target applications.

What happens if a paper battery gets wet?

Since many use a water-based electrolyte, exposure to small amounts of moisture may not immediately disable it, unlike traditional batteries, which can short-circuit. However, comprehensive waterproofing is still needed for consumer devices.

Can paper batteries power a car or a house?

Not currently. Today’s versions are best suited for small electronics. However, research into solid-state derivatives and scaled-up systems is ongoing for potential future use in larger-scale storage and transportation.