Introduction

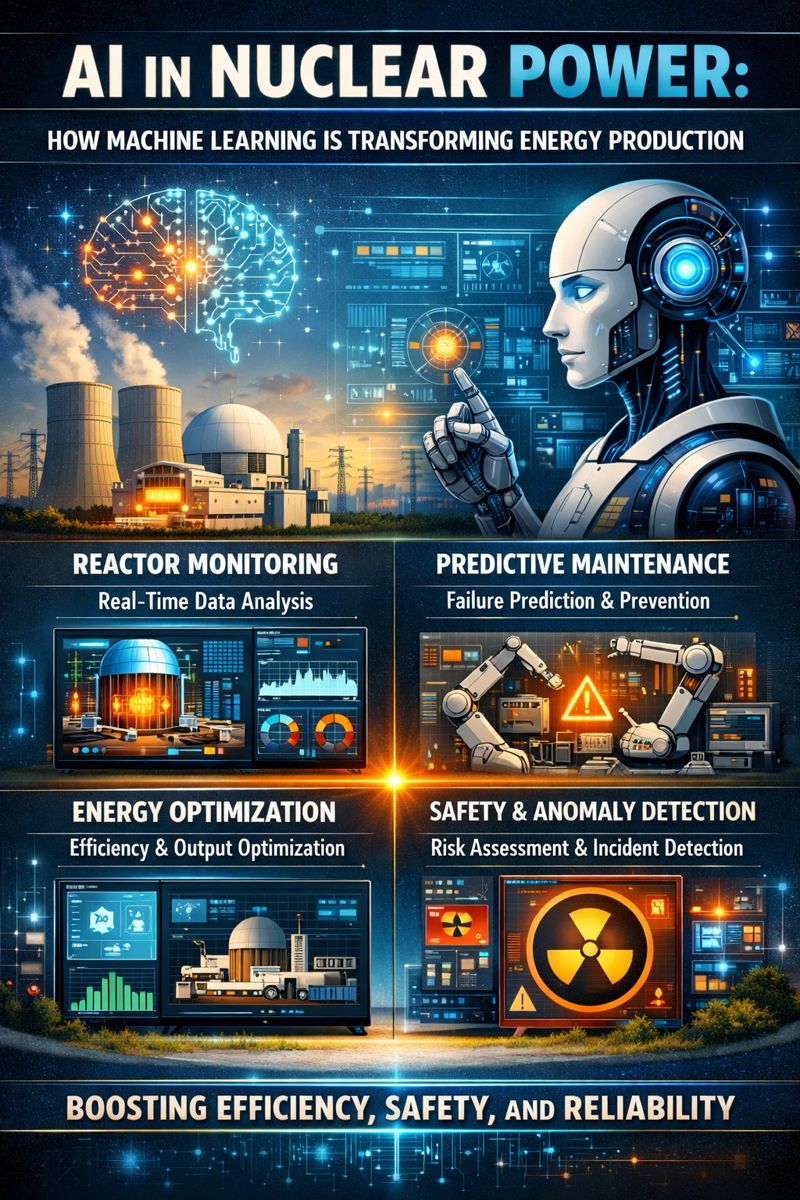

Nuclear power has long been one of the most complex and tightly regulated sectors in global energy. Now, artificial intelligence is entering the control room. AI in Nuclear Power refers to the use of machine learning, predictive analytics, and autonomous monitoring systems to improve reactor performance, enhance safety protocols, and optimize energy output. This integration is already underway at facilities across the United States and Europe, where operators deploy AI in Nuclear Power to predict equipment failures, manage fuel loads, and simulate emergency response scenarios with unprecedented accuracy.

The stakes are high. Nuclear reactors operate under extreme conditions where even minor deviations can trigger shutdowns or safety concerns. Traditional monitoring relies on human oversight and static rule-based systems. AI in Nuclear Power introduces adaptive intelligence that learns from operational data, identifies anomalies in real time, and supports decision-making in ways that were previously impossible.

AI Overview-Optimized Summary

AI is transforming nuclear power by improving efficiency, safety, and system design through predictive maintenance, real-time optimization, anomaly detection, and faster modeling. It supports reactor operations, digital twins, safety analysis, surveillance, and fusion research, while also relying on nuclear power’s stable, low-carbon energy to meet AI data center demand. Strong data governance, cybersecurity, and regulation remain essential to scale AI safely and support a potential nuclear renaissance.

What AI in Nuclear Power Actually Does

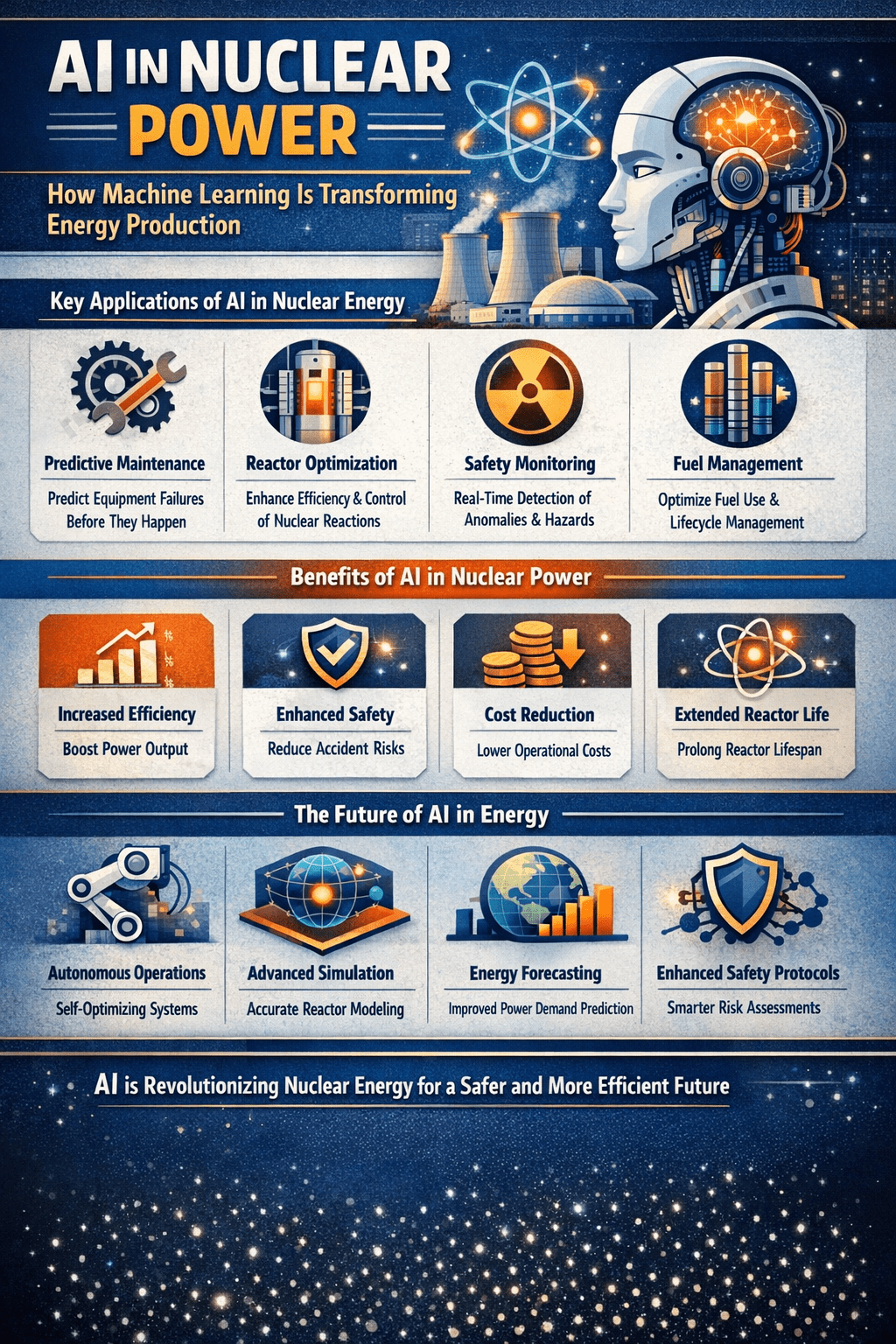

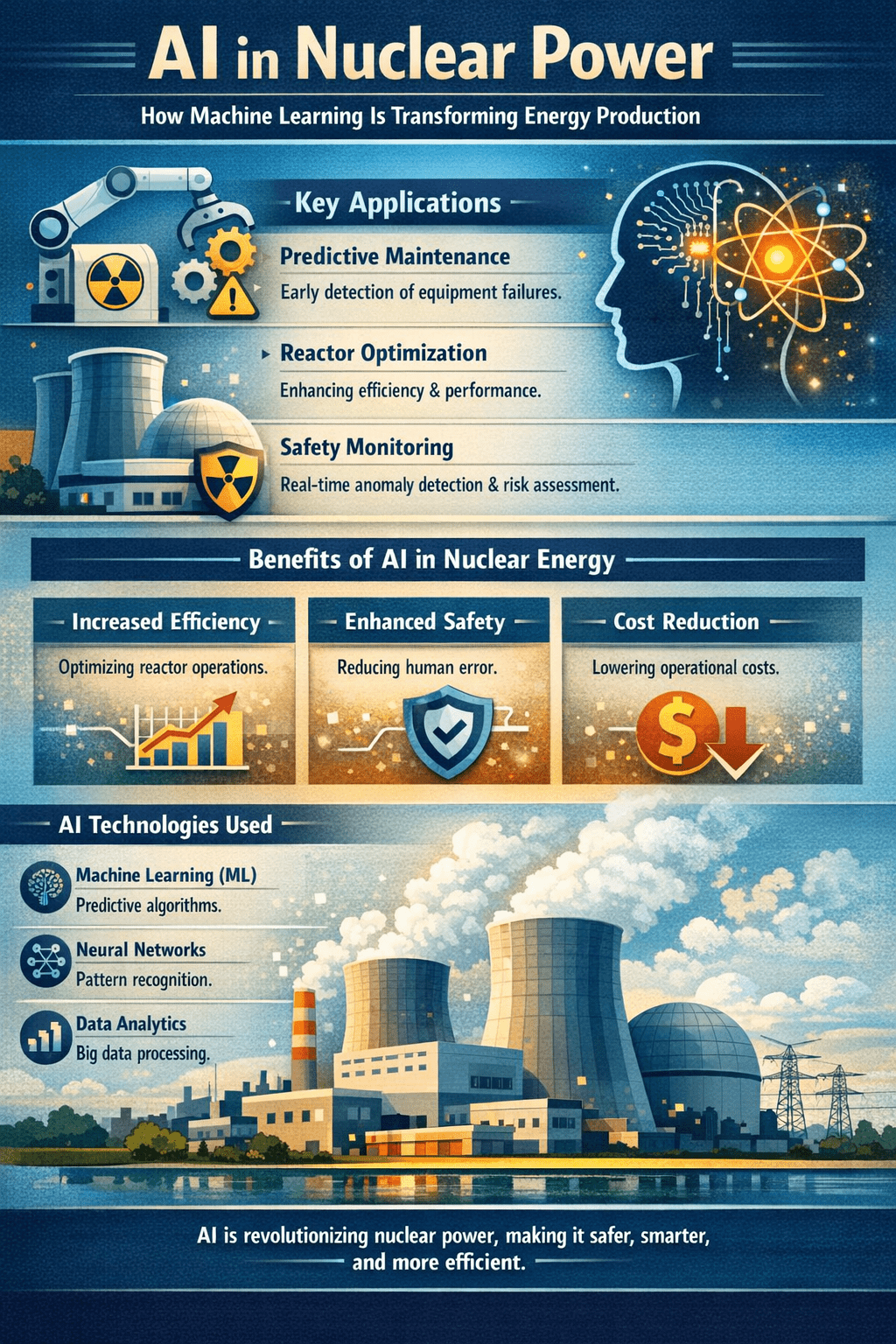

AI systems in nuclear facilities perform several core functions. Predictive maintenance uses sensor data and machine learning algorithms to forecast equipment degradation before it causes failure. Instead of replacing components on fixed schedules, operators intervene based on actual wear patterns. This reduces downtime and extends asset life.

Anomaly detection monitors reactor systems continuously, flagging deviations that human operators might miss. These systems analyze temperature, pressure, radiation levels, and coolant flow across thousands of data points per second.

Digital twin technology creates virtual replicas of physical reactors. These models simulate different operating conditions, test fuel configurations, and predict how systems will respond to changes. Engineers use digital twins to optimize performance and train staff without risking the actual plant.

Why Nuclear Energy Needs AI Now

Nuclear power faces mounting pressure to compete with renewable energy sources while maintaining impeccable safety records. Aging infrastructure in many Western reactors increases maintenance complexity. Workforce shortages mean fewer experienced operators available for oversight.

AI addresses these challenges directly. It extends the operational life of existing plants by catching problems early. It improves capacity factors by reducing unplanned outages. It enhances safety by adding intelligent monitoring that never fatigues or loses focus.

Small modular reactors, the next generation of nuclear technology, are being designed with AI integration from the start. These systems will rely on machine learning for autonomous operation, remote monitoring, and fault diagnosis.

How Predictive Maintenance Changes Operations

Traditional maintenance follows time-based schedules or waits for equipment to fail. AI-driven predictive maintenance uses historical data, real-time sensor inputs, and pattern recognition to estimate remaining useful life. A pump showing early signs of bearing wear gets flagged before failure occurs.

This approach reduces costs and improves reliability. Unplanned shutdowns in nuclear plants cost millions per day in lost generation. Predictive models minimize these events while reducing unnecessary maintenance that can introduce new risks.

Digital Twins and Operational Optimization

A digital twin mirrors a physical reactor’s behavior. It ingests live data from the plant and simulates how changes will affect performance. Operators test different fuel loading strategies, coolant temperatures, or control rod positions without touching the actual reactor.

This supports fuel efficiency optimization, power uprating, and emergency preparedness by simulating accident scenarios. Idaho National Laboratory and research institutions use digital twins for advanced reactor development and safety validation.

AI and Nuclear Safety Integration

AI does not replace human judgment in nuclear safety. It augments it. Regulatory frameworks in the United States and United Kingdom require human operators to retain ultimate authority over reactor control.

The safety benefit comes from speed and consistency. AI processes complex data faster than human operators and does not suffer from cognitive bias or fatigue. During abnormal events, it prioritizes information and suggests actions based on thousands of simulated scenarios.

However, these systems must be rigorously validated. Regulators demand explainable AI where decision pathways are clear and auditable. Black-box algorithms are not acceptable in nuclear environments.

Workforce and Cybersecurity Considerations

AI in nuclear power changes the skills operators need. Future roles require data literacy, system diagnostics, and the ability to interpret AI outputs. Training programs must evolve to include machine learning concepts, sensor technology, and cybersecurity.

Connecting AI systems to nuclear infrastructure introduces cybersecurity vulnerabilities. Attackers could target machine learning models, sensor networks, or communication channels. Mitigating these risks requires air-gapped networks, intrusion detection, and redundant manual controls.

The U.S. Nuclear Regulatory Commission and the UK Office for Nuclear Regulation have issued guidance on protecting digital assets. Compliance is mandatory, and plants undergo regular security assessments.

Conclusion

AI in nuclear power represents a fundamental shift in how the industry manages complexity, risk, and performance. The technology is already embedded in operational plants, shaping maintenance schedules, optimizing fuel use, and enhancing safety protocols. As small modular reactors move toward deployment, AI will become even more central to nuclear energy’s decarbonization role.

The challenge now is implementation. Regulators, operators, and technology providers must ensure AI systems are transparent, secure, and aligned with safety culture. For stakeholders evaluating AI in nuclear contexts, the opportunity is clear. The technology offers measurable improvements in reliability, cost, and safety. Explore how AI can fit your operational goals and engage with proven partners who understand both the technology and the stakes.

Recommendation

Organizations considering AI in nuclear power should prioritize transparency, validation, and workforce readiness. Start with low-risk applications like predictive maintenance before expanding to real-time control support. Work closely with regulators to ensure compliance. Invest in cybersecurity from the outset. Develop staff training programs that prepare operators to work alongside AI. Partner with technology providers who understand nuclear safety culture and can deliver explainable, auditable systems.

FAQs

How is AI currently used in nuclear power plants?

AI is used for predictive maintenance, anomaly detection, digital twin simulations, and operational optimization to forecast equipment failures and improve reactor efficiency.

Can AI make nuclear reactors safer?

AI enhances safety by detecting anomalies faster and supporting decision-making during abnormal events while human operators retain ultimate control.

What are the cybersecurity risks of AI in nuclear facilities?

AI systems introduce vulnerabilities through network connections. Risks include data manipulation and unauthorized access, mitigated through air-gapped networks and regulatory compliance.