Introduction

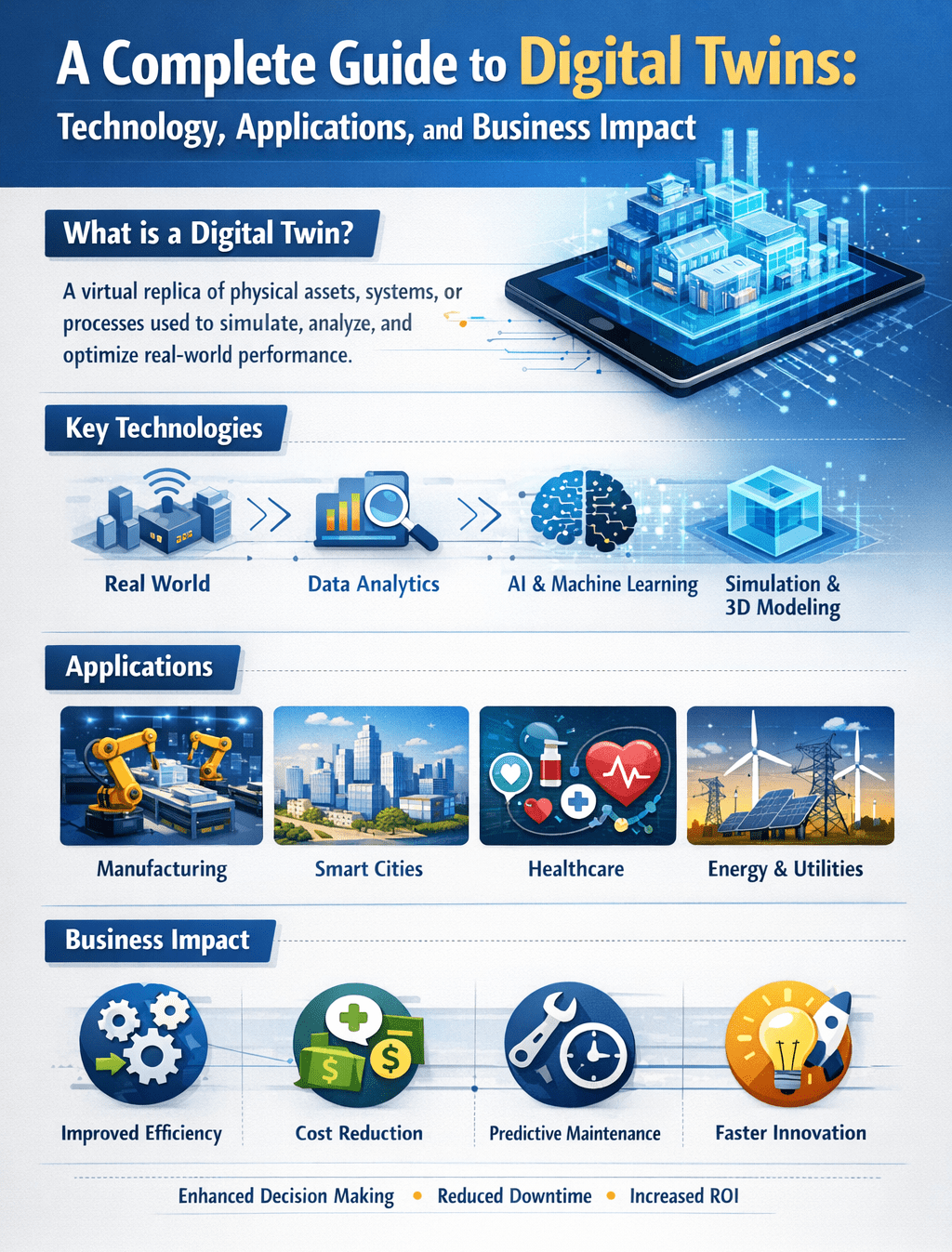

Digital Twins represent a fundamental shift in how we manage the physical world. A Digital Twins is a dynamic, virtual representation of a physical object or system, synchronized with its real-world counterpart using real-time data. This technology allows for unprecedented simulation, monitoring, prediction, and optimization of assets throughout their entire lifecycle.

From a single component like a jet engine to entire cities and global supply chains, the scope of Digital Twins technology is vast and transformative. As industries undergo digital transformation, these virtual replicas are becoming critical for enhancing operational efficiency, enabling predictive maintenance, and driving innovation across manufacturing, healthcare, urban planning, and more.

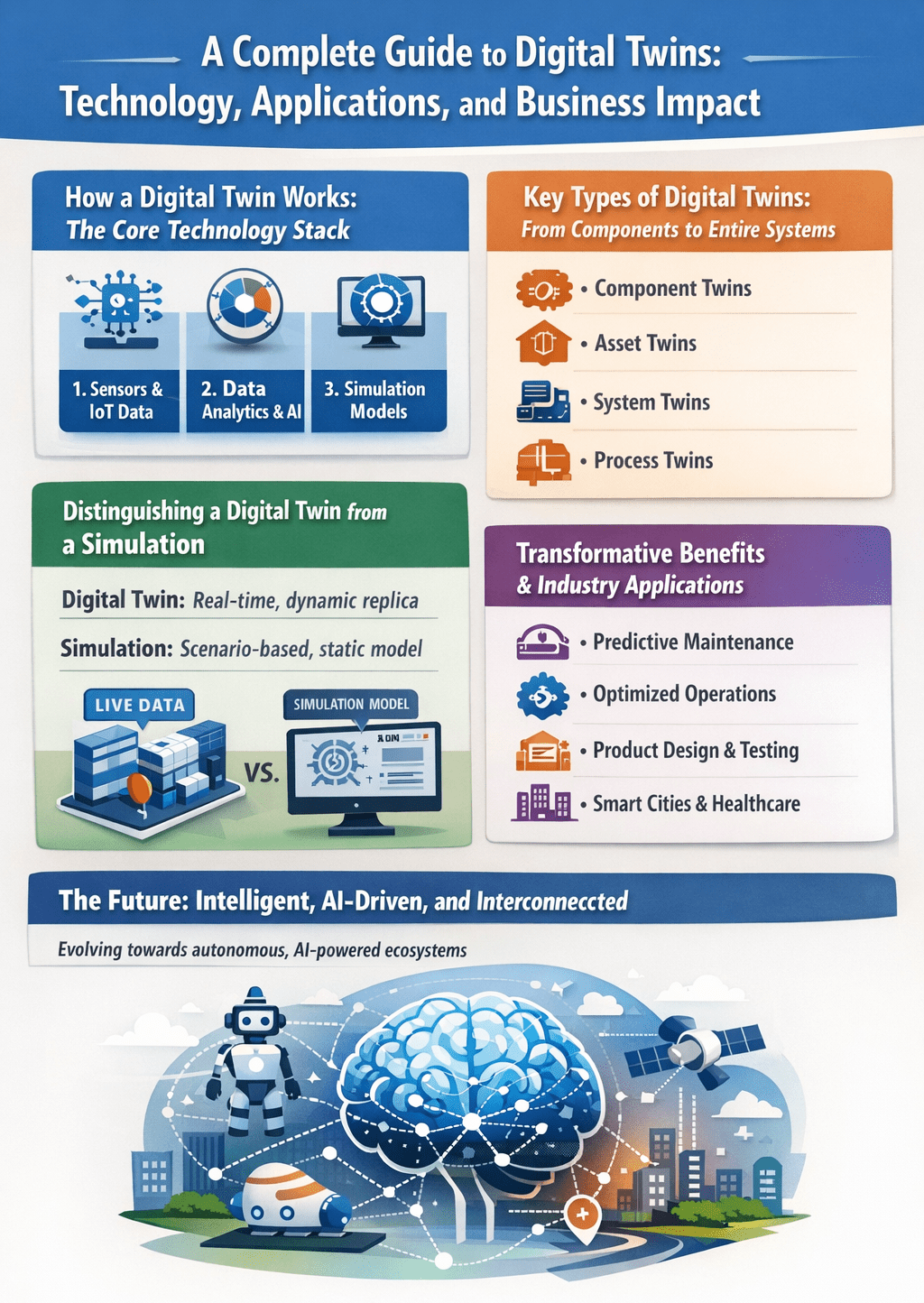

How a Digital Twin Works: The Core Technology Stack

Creating and operating a digital twin involves a continuous, five-step feedback loop that connects the physical and virtual worlds. It begins with data collection, where IoT sensors attached to a physical asset capture live data on performance, environment, and condition.

This data flows through a connectivity layer, or middleware, to a central system where a virtual model is built and maintained. The system achieves real-time synchronization, constantly updating the digital model to mirror the current state of the physical asset.

An analytics engine, often powered by AI and machine learning, then processes this data for simulation and predictive analysis. Finally, the insights generated are delivered back to operators via visualization dashboards, enabling data-driven actions like preemptive maintenance or process optimization.

Key Types of Digital Twins: From Components to Entire Systems

Digital twins are categorized by their scope and complexity, often operating together within a single environment. Understanding these types clarifies their application.

- Component/Part Twins: These are the most fundamental type, representing individual components such as a valve, sensor, or motor. They provide granular insight into the health and performance of specific parts.

- Asset Twins: An asset twin models a functional unit made of multiple interacting components, like a pump system or a car engine. It reveals how working together affects overall performance parts.

- System/Unit Twins: This type scales up to show how multiple assets combine to form a complete, integrated system. An example is a digital twin of a production line or a building’s climate control system, optimizing interactions between subsystems.

- Process Twins: Offering the broadest view, process twins simulate how multiple systems work together across an entire facility or workflow. They can model a full manufacturing plant, a city’s traffic management, or an end-to-end supply chain to maximize overall operational efficiency.

Distinguishing a Digital Twin from a Simulation

A common point of confusion is the difference between a digital twin and a simulation. While both use digital models, a simulation is typically a static, one-time analysis based on predefined data to study a specific process.

A digital twin is distinguished by its persistent, two-way connection to a specific physical asset. It is a living model that evolves in real-time, continuously learning from new data to reflect current conditions and predict future states. This dynamic link enables ongoing optimization rather than isolated analysis.

Transformative Benefits and Industry Applications

The business value of digital twins is substantial, with a high percentage of adopting companies reporting strong returns on investment. Core benefits include accelerated research and development through virtual prototyping, greater operational efficiency, enhanced oversight for predictive maintenance, and improved scalability for testing new configurations safely.

These benefits are realized across nearly every sector:

- Manufacturing and Industrial Operations: Applied across product engineering, bespoke design workflows, production efficiency improvement, and equipment health forecasting to support intelligent, data-driven factory environments.

- Healthcare: Applications range from creating digital twins of hospital facilities to optimize resources to pioneering personalized medicine through virtual models of human organs or genetics.

- Aerospace and Automotive: Essential for the development, simulation, and lifecycle management of advanced vehicles and aircraft, with early adoption tracing back to aerospace research initiatives such as NASA’s Apollo missions.

- Smart Cities and Infrastructure: City authorities apply large-scale digital twin models to improve traffic flow, oversee energy distribution, support sustainable planning, and strengthen emergency preparedness and response systems.

- Supply Chain & Retail: Models of logistics networks, warehouses, and even customer personas help optimize routes, inventory, and personalized experiences.

The Future: Intelligent, AI-Driven, and Interconnected

The evolution of digital twins points toward more intelligent and autonomous systems. A key trend is deeper AI integration, where predictive and generative AI will enable digital twins to forecast failures, suggest optimizations, and even automate decision-making.

They are also becoming more accessible through cloud-based “Digital Twin as a Service” (DTaaS) models and more immersive via integration with Extended Reality (XR) for advanced visualization and training. Furthermore, the focus is expanding to large-scale, interconnected ecosystems of digital twins—linking models of buildings, energy grids, and transportation to manage entire cities or planetary systems like climate. This expansion brings to the forefront critical considerations for security, data privacy, and ethical governance.

Final Perspective

Digital twins are transitioning from a specialized engineering tool to a foundational component of modern, data-driven enterprises. They close the loop between the physical and digital, transforming passive assets into interconnected sources of continuous insight. The organizations that effectively harness this technology will gain a significant competitive advantage through superior efficiency, innovation, and resilience. The question is no longer if digital twins will be widely adopted, but how quickly industries can integrate them into their core operational strategies.

FAQs

What is the main difference between a digital twin and a standard 3D model?

A 3D model is a static visual representation, while a digital twin is a dynamic, data-driven model that simulates real-time behavior and performance of its physical counterpart.

Are digital twins only useful for large manufacturing companies?

No, while prevalent in manufacturing, digital twin applications are rapidly expanding into healthcare, retail, urban planning, and supply chain management, with cloud-based services (DTaaS) making them more accessible to businesses of all sizes.

What are the biggest challenges in implementing a digital twin?

Key challenges include ensuring real-time data synchronization, managing the complexity of model integration, establishing interoperability between different systems, and addressing ongoing concerns around data security and trustworthiness in cyber-physical environments.