Introduction

Computer Simulation Technology is transforming how industries design, test, and optimize complex systems without relying on costly real-world experiments. By using advanced computational models, businesses and researchers can predict outcomes, reduce risk, and accelerate innovation across engineering, healthcare, climate science, and artificial intelligence.

As Computer Simulation Technology continues to evolve, it enables faster decision-making, improved accuracy, and scalable digital experimentation through virtual environments and data-driven modeling. This approach supports scenario analysis, performance optimization, and system validation before real-world deployment.

Today, Computer Simulation Technology plays a critical role in digital transformation, powering smart manufacturing, autonomous systems, and next-generation research where precision, efficiency, and innovations are essential.

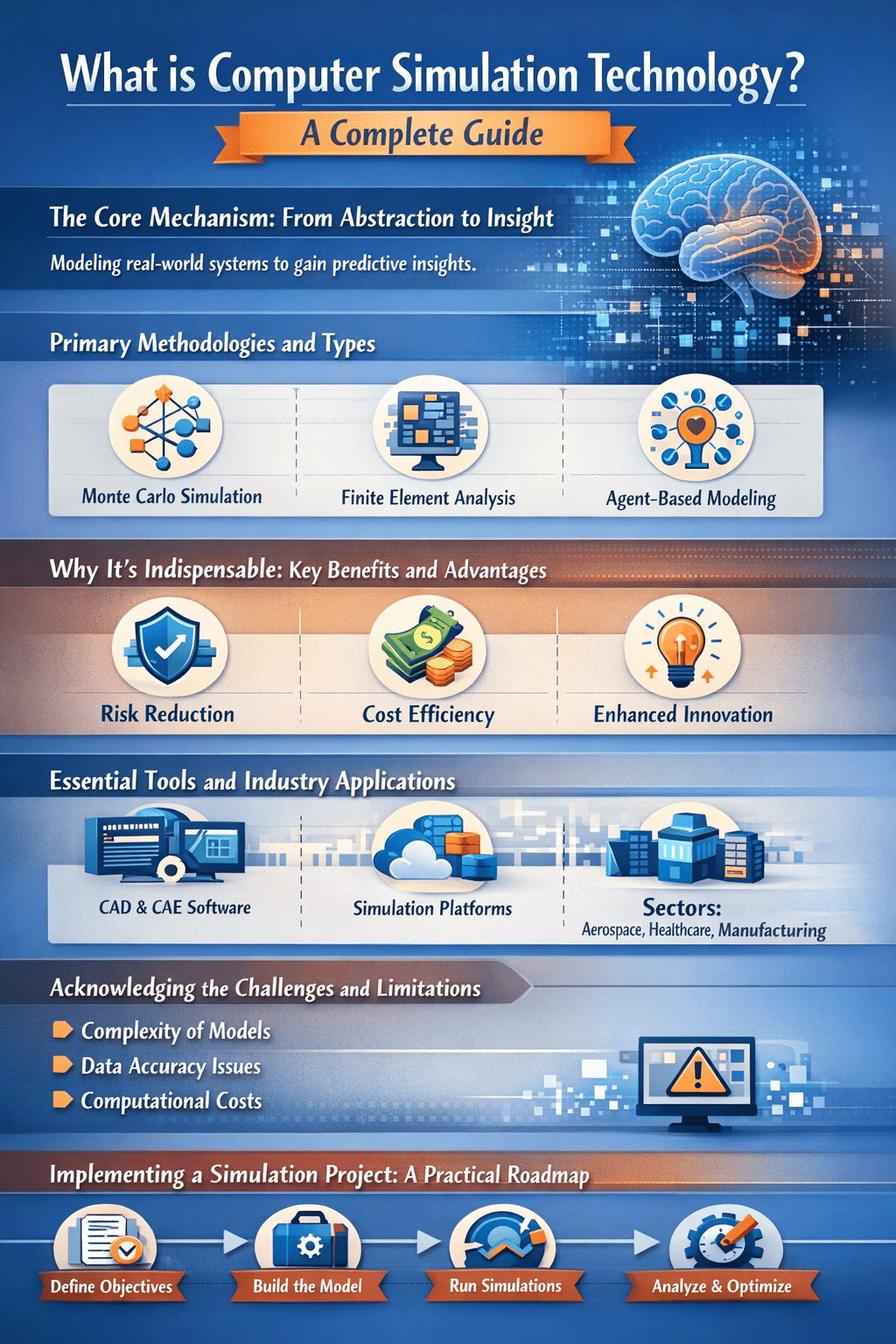

The Core Mechanism: From Abstraction to Insight

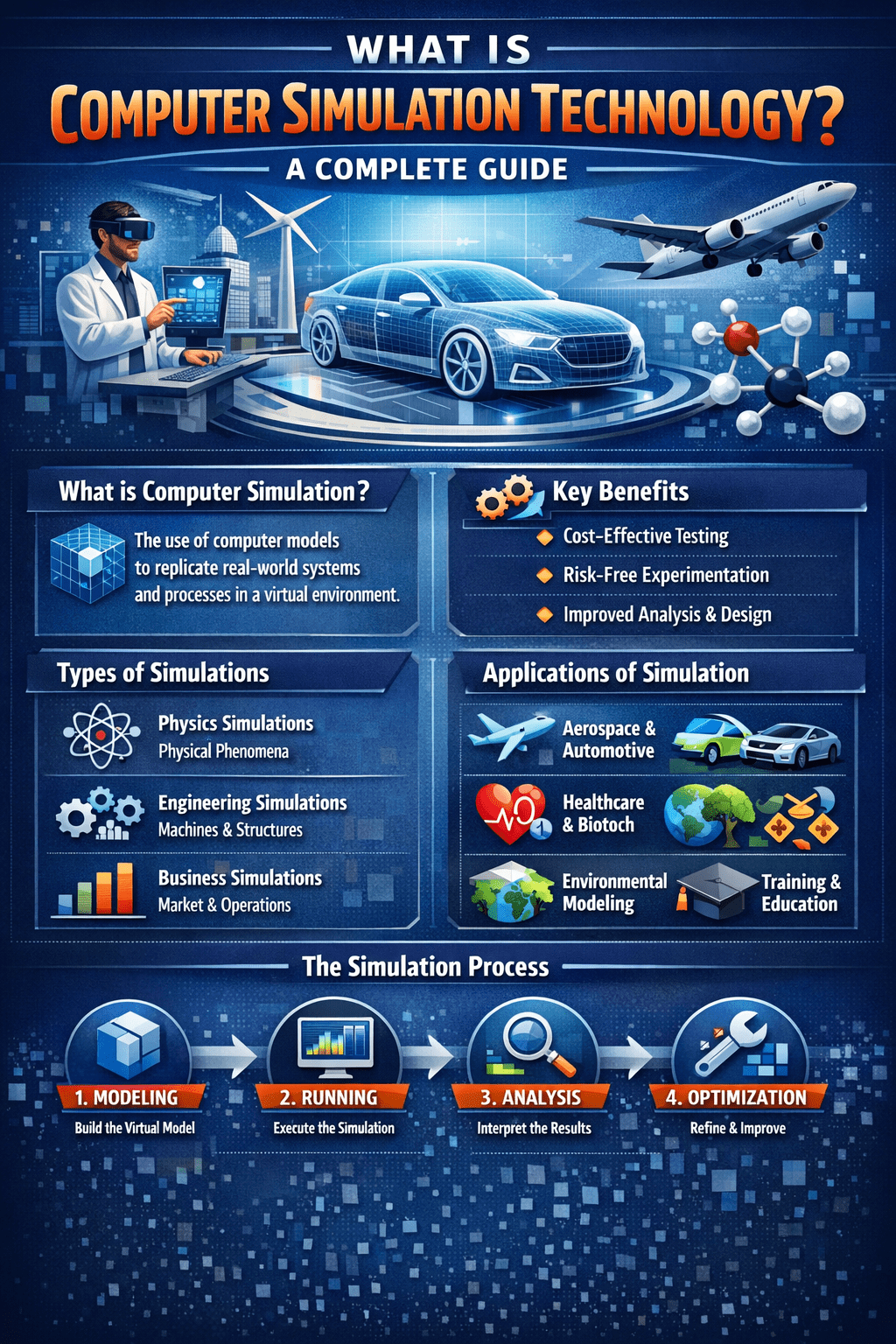

Computer simulation is not advanced animation. It is a rigorous computational experiment involving three key stages:

- Model Creation: The real-world system is abstracted into a conceptual model defined by mathematical logic and rules.

- Execution: Computational power solves the model’s equations over simulated time, dynamically processing interactions and stochastic events.

- Analysis: The output data is visualized and analyzed to understand system performance, identify bottlenecks, and forecast future states.

Primary Methodologies and Types

Different problems require different simulation approaches. The main types include:

- Discrete-Event Simulation (DES): Models systems where state changes occur at distinct points in time (e.g., customer service queues, logistics networks). It is a fundamental operations research technique.

- Agent-Based Modeling (ABM): Simulates the actions and interactions of autonomous “agents” (e.g., crowd behavior, market dynamics) to assess their effects on the whole system.

- Continuous Simulation: Models systems where state variables change continuously over time (e.g., fluid dynamics, physiological processes).

- System Dynamics: Focuses on high-level feedback loops and time delays within complex systems (e.g., economic models, ecosystem management).

Why It’s Indispensable: Key Benefits and Advantages

Organizations adopt simulation technology for compelling reasons:

- Risk-Free Experimentation: Test new policies, designs, or procedures in a safe, virtual environment without real-world consequences.

- Cost and Time Efficiency: Identify optimal solutions and avoid costly mistakes before committing physical resources.

- Deep System Insight: Uncover hidden interdependencies and understand “why” things happen, not just “what” happened.

- Enhanced Training: Provide immersive, repeatable practice environments for high-stakes skills, from surgery to flight training.

Essential Tools and Industry Applications

Implementation relies on specialized software. Common tools include AnyLogic (multi-method simulation), ANSYS (engineering and physics), Siemens Tecnomatix (manufacturing), and open-source frameworks like SimPy. These tools bring simulation to life across sectors:

- Engineering & Manufacturing: For product design (digital prototyping), factory layout optimization, and robotics programming.

- Healthcare: To model patient flow through hospitals, test public health policies, and train surgical teams.

- Logistics & Supply Chain: To improve efficiency across warehousing processes, logistics routes, and stock control systems.

- Emerging Frontiers: Integration with Digital Twin technology creates live, data-driven replicas of physical assets, while Generative AI is beginning to assist in model creation and scenario generation.

Acknowledging the Challenges and Limitations

While powerful, simulation has constraints:

- Model Validity: A simulation’s accuracy is limited by the quality of its underlying assumptions and input data. “Garbage in, garbage out” is a fundamental principle.

- Resource Intensity: Building and running high-fidelity models requires significant expertise, time, and computational power.

- Interpretation Complexity: Results require skilled analysis to avoid misleading conclusions; the model is a guide, not an infallible oracle.

Implementing a Simulation Project: A Practical Roadmap

A successful simulation study follows a structured path:

- Define the Problem: Clearly articulate the specific question you need to answer.

- Develop the Conceptual Model: Map out the system’s key components, rules, and metrics.

- Build and Verify the Computer Model: Implement the conceptual model in software and ensure it runs correctly.

- Validate with Real Data: Calibrate the model by comparing its output to known, real-world performance.

- Experiment and Analyze: Run your “what-if” scenarios and rigorously analyze the results to inform decisions.

Final Perspective

Computer simulation technology has evolved from a niche analytical tool into a cornerstone of modern engineering, science, and business strategy. Its ability to compress time, reveal hidden truths, and de-risk innovation makes it indispensable for solving tomorrow’s complex problems. As it converges with AI and real-time data streams, its evolution into adaptive, intelligent digital twins will further blur the line between the virtual and physical worlds. To leverage its power, begin with a well-defined pilot project that addresses a concrete operational challenge.

FAQs

What is the difference between computer modeling and simulation?

Computer modeling is the creation of a static representation of a system. Simulation is the dynamic execution of that model over time to generate data and observe behavior.

What are the main benefits of using simulation technology?

The core benefits are risk reduction by testing scenarios safely, significant cost savings by optimizing decisions before implementation, and gaining deeper insight into complex system behaviors that are impossible to observe directly.

Which industries use simulation technology the most?

It is heavily utilized in aerospace and automotive engineering for design, in manufacturing for process optimization, in healthcare for system planning and training, and in logistics for supply chain management.