Introduction

The next major shift in food service is not about a new cuisine but about the complete removal of the human hand from the cooking process. This transition is being led by the AI Autonomous Meal Kitchen, a category definitively established by the Circus Group CA-1. This serially produced machine is now operating in major commercial environments, representing the first fully realized system where AI Autonomous Meal Kitchens converge to manage the entire meal journey.

For industry leaders, understanding this AI Autonomous Meal Kitchen is crucial to navigating the future of retail, catering, and logistics.

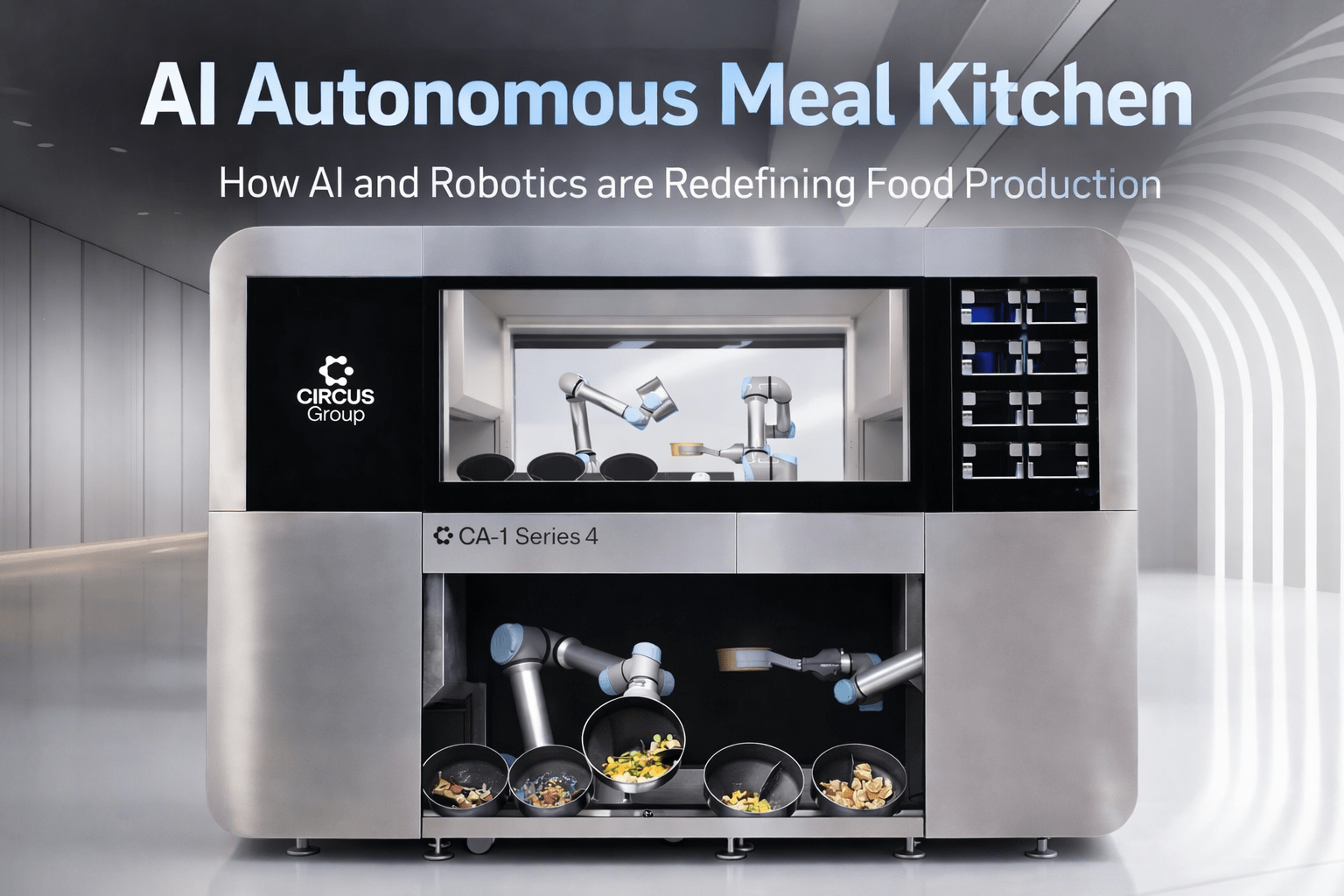

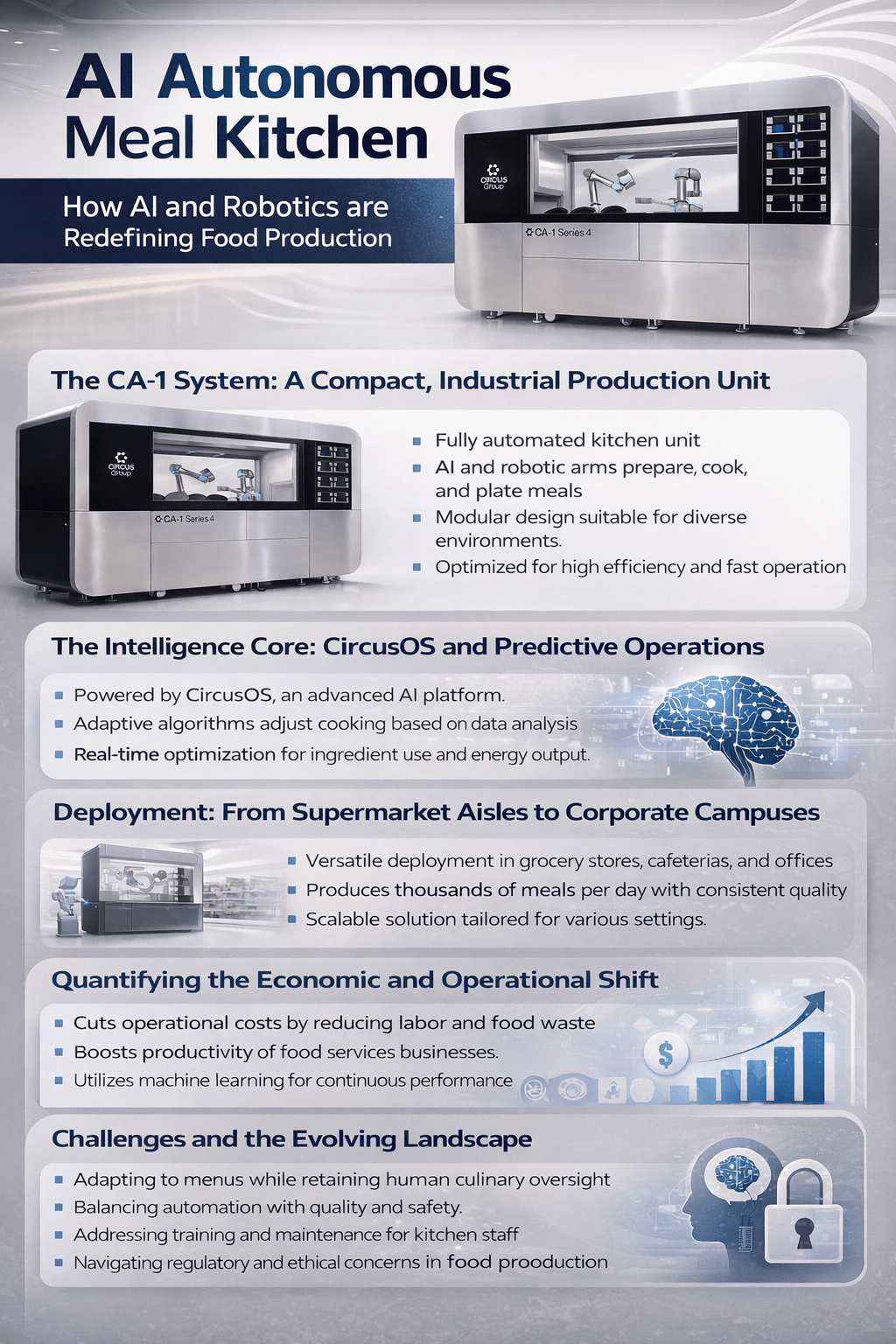

The CA-1 System: A Compact, Industrial Production Unit

The Circus Group CA-1 is a fully autonomous, AI-driven robotic kitchen engineered for industrial-scale output. Operating within a compact 7 square meters, it functions as a closed-loop production cell. Its core includes 36 refrigerated ingredient silos, enabling millions of recipe combinations. Robotic arms handle all dispensing, cooking in precision induction pots, and plating. An integrated self-cleaning dishwasher and AI vision systems ensure consistent hygiene and quality control, completing a start-to-finish process with minimal human intervention.

The Intelligence Core: CircusOS and Predictive Operations

Autonomy is powered by CircusOS, an AI-native operating system that coordinates the entire hardware stack. This intelligence layer moves beyond simple execution to predictive management. It handles real-time ingredient tracking, performs predictive demand modeling to align production with customer flow, and can even personalize meal recommendations. This transforms the unit from a passive machine into an active, optimizing node within a food service network, capable of adjusting its own production schedule based on learned patterns.

Deployment: From Supermarket Aisles to Corporate Campuses

The CA-1 has moved from concept to mass production, with significant milestones proving its commercial viability. Its fourth-generation (Series 4) model is 450 kg lighter and operates at twice the speed of its predecessor, now incorporating AI voice ordering. Live deployments are diverse: it operates in REWE supermarkets in Germany under the “Fresh & Smart” brand, serves as the first enterprise installation at Meta’s Munich office, and provides autonomous catering for Mercedes-Benz staff. A manufacturing partnership with Celestica supports the production of thousands of units annually to meet a reported backlog exceeding 8,500 orders.

Quantifying the Economic and Operational Shift

The economic impact of the CA-1 is measurable and significant. With a production capacity of 120 dishes per hour (roughly 2,000 daily), a single unit can offset substantial labor costs. The system is reported to reduce operational costs by up to 95% in suitable environments by slashing dependency on kitchen staff for prep, cooking, and cleaning. While the capital investment for a unit is approximately €250,000, the shift in business model is clear: it transitions food production from a high-variable-cost model reliant on skilled labor to a high-efficiency, fixed-cost asset optimized for consistent throughput and minimal waste.

Challenges and the Evolving Landscape

Adoption hurdles remain, primarily the upfront capital expenditure and the need for space redesign. Consumer acceptance of machine-prepared meals is an ongoing test. However, the scale of deployment and order backlog indicates strong market confidence. The trajectory points toward further specialization for different cuisine types and deeper AI integration with supply chains. The success of voice ordering and corporate deployments suggests a future where hyper-fresh, automated food production becomes a standard amenity in workplaces, retail spaces, and beyond.

Conclusion

The Circus Group CA-1 has evolved from a prototype to a commercially deployed, mass-produced platform. Its expansion into supermarkets, corporate offices, and industrial caterers in 2025 marks an inflection point. This signals a structural shift in food service economics, prioritizing data-driven efficiency, relentless consistency, and localized production. The question is no longer if autonomous production will find its place, but how swiftly different sectors will adapt to an infrastructure where the core production asset is an intelligent, automated system. Assess your organization’s readiness for this operational shift now.

Recommendation

For businesses evaluating this technology, begin by analyzing your meal volume and labor cost structure against the CA-1’s 2,000-dish daily capacity. A pilot in a controlled, high-volume environment like a corporate cafeteria is the logical first step to gauge customer response and operational fit. Critically, engage with providers on their AI’s ability to integrate with your existing inventory and sales platforms, as this connectivity is key to realizing the full predictive and waste-reduction benefits.

FAQs

Can the CA-1’s menu be easily changed or customized?

Yes. With 36 ingredient silos and software-defined recipes, menus can be updated remotely via the CircusOS platform, allowing for limitless combinations and seasonal changes without hardware modification.

How does the system ensure food safety and consistency?

AI computer vision monitors cooking and plating in real-time, while automated, integrated cleaning sanitizes all cooking and serving ware after each use, ensuring hygienic standards that surpass manual variability.

Is the system truly autonomous, and what maintenance does it require?

It operates autonomously for cooking and cleaning. Human intervention is needed only for restocking ingredients (approximately once per day for high volume) and scheduled technical maintenance, totaling about one labor hour per day.