Introduction

Lab-Grown Meat—also called cultured, cultivated, or cell-based meat—is reshaping how humans produce and consume animal protein. Traditional meat production, based on raising livestock, uses vast amounts of land, water, and feed and contributes significantly to emissions. In contrast, Lab-Grown Meat is made by culturing real animal cells in controlled environments, offering a more ethical and resource-efficient way to meet rising global protein demand. According to industry definitions, Lab-Grown Meat is biologically identical to conventional meat but produced without raising or slaughtering animals, directly addressing environmental strain and animal welfare concerns.

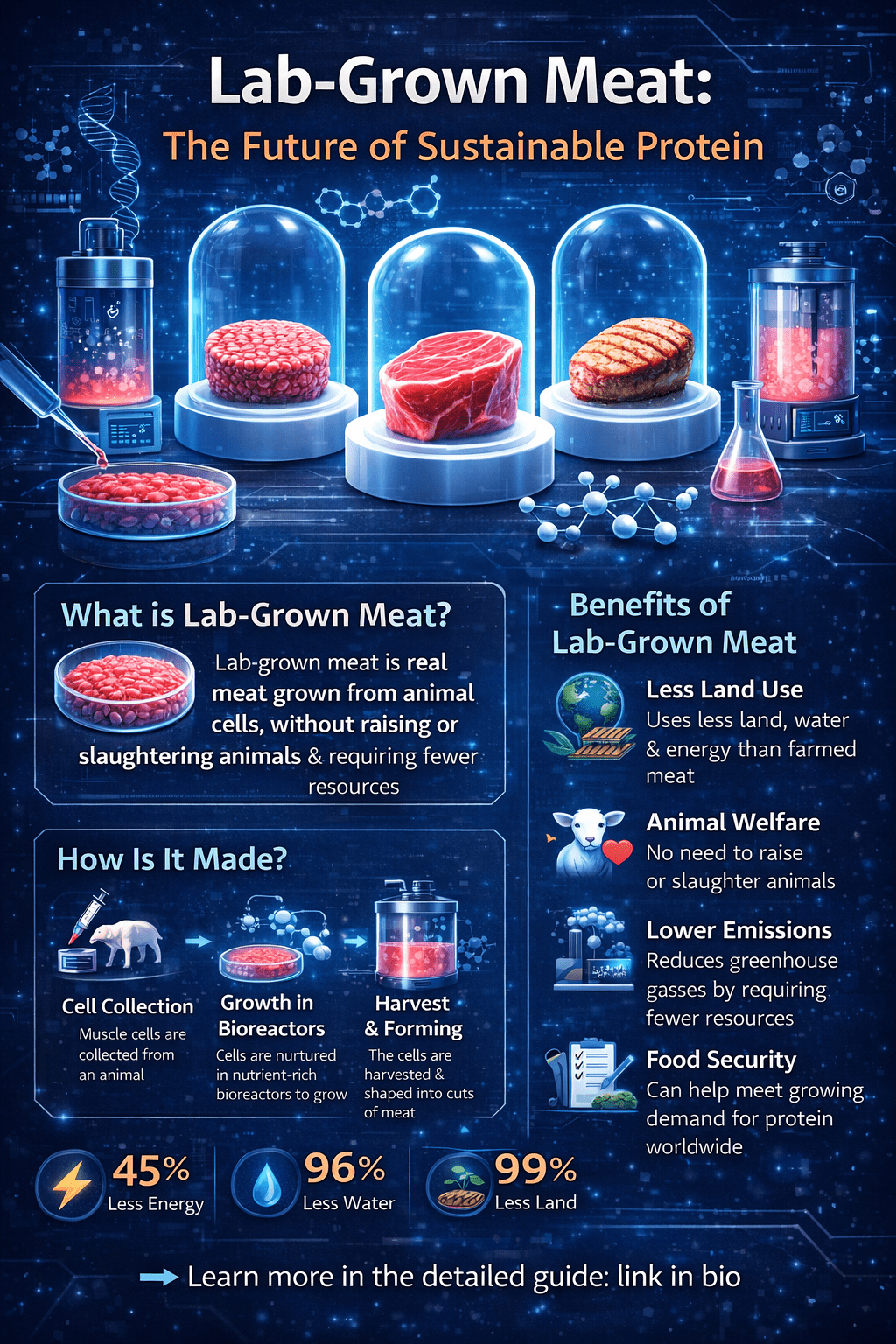

What Lab-Grown Meat Is: How It Works

Lab-grown meat uses cell culture and tissue engineering techniques to reproduce muscle, fat, and connective tissues outside the animal’s body. In practice, animals such as cattle, pigs, or poultry provide a small sample of stem cells, which are then nurtured in nutrient‑rich “culture media” inside bioreactors that mimic body conditions. These cells multiply and differentiate into real meat tissue through a process akin to industrial fermentation.

This technology, often described as part of cellular agriculture, allows meat production independent of conventional farming. Because cultured meat uses real animal cells, it replicates the sensory and nutritional profile of traditional meat more closely than plant‑based alternatives.

Production Process: From Cells to Meat

Cell Sourcing: Stem cells are extracted from an animal or obtained from cell banks. These pluripotent cells have the ability to develop into key tissues such as muscle and fat.

Culturing: Cells are placed in bioreactors with a nutrient medium supplying amino acids, glucose, oxygen, vitamins, and growth factors needed for cell proliferation.

Multiplication and Differentiation: Under controlled conditions, cells grow and form structured tissue. Food scientists may employ advanced scaffolding techniques to mimic the texture and structure of whole cuts.

Harvesting: Once cells have matured into muscle and fat, the resulting tissue is harvested, processed, and shaped into products like burgers, chicken strips, or meatballs.

This process distinguishes lab-grown meat from plant-based substitutes by focusing on real biological growth rather than simulacra of meat texture.

Environmental and Ethical Benefits

Lab-grown meat offers compelling impacts:

Reduced Environmental Footprint: Cultured meat production uses significantly fewer natural resources than livestock agriculture. Life cycle assessments suggest reductions in land use, water use, and emissions when compared to conventional meat—potentially cutting greenhouse gas emissions and habitat loss.

Animal Welfare: Because the initial cell sample can be obtained with minimal harm and no slaughter, lab-grown meat addresses ethical concerns tied to animal rearing and slaughter.

Food Safety Improvements: Cultured meat controls sterility and conditions closely, which may reduce the risk of contamination and eliminate the need for antibiotics commonly used in livestock production.

Taken together, these advantages position lab-grown meat as a key part of future food systems focused on sustainability and humane production.

Challenges and Practical Considerations

Scalability and Cost: Production costs remain high due to expensive culture media and bioreactor systems. Industry pressure is on to scale up to commercial viability.

Taste and Texture Consistency: Producing whole cuts (e.g., steak texture) requires sophisticated scaffolding and cell alignment techniques.

Consumer Acceptance: While the technology is scientifically robust, consumer perception and cultural acceptance vary widely. Regulatory language and labeling also influence uptake.

Addressing these challenges is central to mainstream adoption and meaningful market impact.

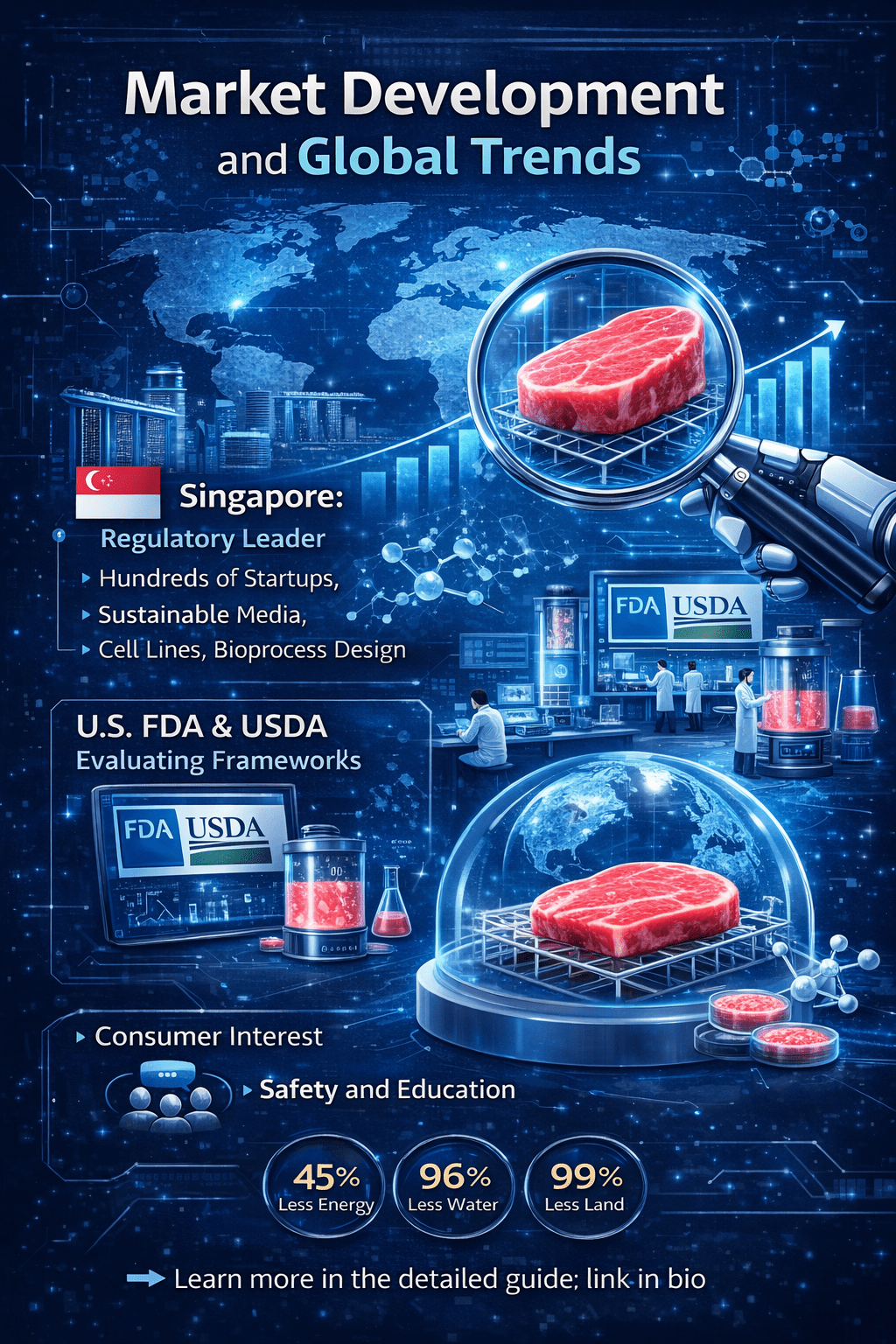

Market Development and Global Trends

Globally, the cultured meat sector is expanding, with hundreds of startups focused on cell lines, bioprocess design, and sustainable media development. Singapore has emerged as a key regulatory leader, while the U.S. FDA and USDA continue evaluating safety frameworks for commercialization. Consumer surveys show interest in lab-grown options but highlight the need for clear education on benefits and safety.

Technological breakthroughs, such as advanced bioreactors and scaffolded growth, are helping bridge the gap between research and commercial products, enabling thicker, more realistic tissue structures.

Conclusion

Lab-grown meat is a scientifically grounded, ethically compelling, and environmentally significant evolution in protein production. By harnessing cellular agriculture, biotechnology, and controlled culturing processes, this innovation stands to reshape global food supply dynamics. As production scales and challenges are addressed, lab-grown meat could become a core component of sustainable diets, reducing pressure on ecosystems and improving animal welfare while meeting global protein needs.

Recommendation

Food industry stakeholders should invest in scalable bioreactor technologies, optimize culture media, and develop edible scaffold systems to enhance product texture and taste. Engagement with regulators to clarify labeling and safety standards will build consumer trust. Clear communication campaigns explaining environmental and ethical benefits will improve acceptance. Cross-sector collaboration with sustainability scientists, bioprocess engineers, and market strategists will accelerate meaningful adoption.

FAQs

Is lab-grown meat the same as cultured meat?

Yes. Lab-grown meat is another term for cultured or cell‑based meat made by growing animal cells outside the animal.

Does lab-grown meat use animals?

It uses a small cell sample but does not require raising or slaughtering animals.

Will lab-grown meat reduce environmental impact?

Evidence suggests it can lower land and water use and greenhouse gas emissions compared with conventional meat.